Products

Products list

產品搜索

Products search

Contact us

Contact us

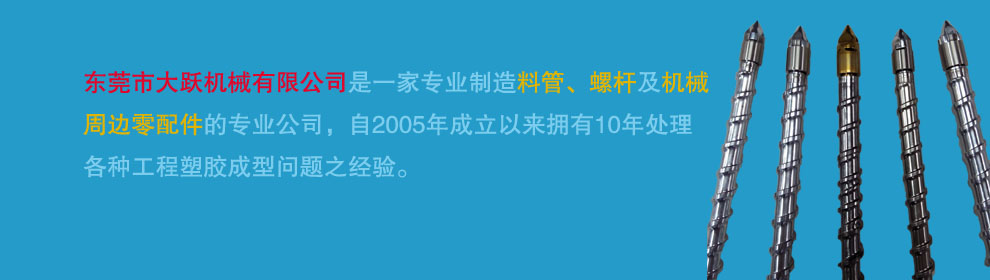

Dongguan Dayue Machinery Co. Ltd.

Contact: Mr. blue

Contact number: 13922501330

Telephone: 0769-87094259/82387537

Fax: 0769-87094013

URL: www.flsly.com

Address: No. 1, Zhongshan North Road West Road, Changan Town, Dongguan City, Guangdong Province

2016 rapid precision positioning injection molding |

| Published:2015-12-18 14:19:00Click to rate: |

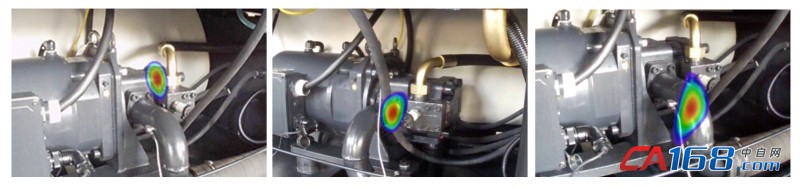

Its high technology for the domestic well-known injection molding machine manufacturer A to provide noise sound source localization solution, to help them find out the root causes of noise and put forward suggestions for improvement. Project background Too large injection molding machine noise not only affect the normal production, but also very easy to cause hearing damage to workers, the greater harm to the enterprise. Therefore, the injection molding machine noise size is an important factor affecting the purchase of users. Injection molding machine noise mainly from its hydraulic system and mechanical parts, in the face of many of these devices, the structure of the complex part, how to reduce or even eliminate noise noise, improve product quality? A company as one of the largest injection molding machine manufacturers, its production of various brands of injection molding machine covering all fields of plastic processing industry. To provide users with a more comfortable environment, A company hopes its high-tech help to find the cause of the noise of a certain brand of injection molding machine, and provide solutions. Solution KeyVES sound camera rapid initial positioning Its high technology for the A program, the first use of the KeyVES sound camera on the overall noise source of the initial positioning of the injection molding machine, the way can be intuitive to show the maximum noise radiation location and possible components. Specific procedures: KeyVES sound camera observed in the distance, to see the largest overall noise in the pump head, then KeyVES sound camera near parts, can be more clearly see the main noise sources of import and tubing, especially joint and bend.  Rapid location of noise source of injection molding machine by KeyVES sound camera SignalPad測試軟件精準定位主要噪聲源SignalPad test software precision positioning of the main source of noise After defining the primary noise source components, the high-tech injection molding machine of pump head, tubing, siding peripheral device has to do the analysis, including hydraulic pressure signal acquisition and feature analysis, noise measurement and analysis, vibration measurement and characteristics analysis and frequency response function measurement and so on a series of tests. Because the driving force of the injection molding machine comes from the hydraulic pressure, the characteristic analysis of the pressure signal can help to locate and understand the source of the noise. First, by using software testing SignalPad on noise and vibration signal feature analysis to determine the noise and vibration frequency of the excitation source in the fundamental 406Hz around its harmonic part. Then, by tapping on the experiment of frequency response test, the hammer respectively on part of the pump head and its vicinity: main frame column and side plate of the tank and motor under the floor, oil pipe and the oil outlet pipe (elbow), access to these parts of the main resonance frequency. The experimental results show that the resonance frequency and the excitation frequency are close to the 406Hz components of the oil suction pipe and the oil pipe (elbow), and these two places are the same as the KeyVES sound camera positioned by the noise source location. Therefore, the main source of the noise of the injection molding machine can be determined by the oil suction pipe and the oil outlet pipe (elbow).  Suggestions for improvement of the head and the nearby area of the percussion hammer According to certain test noise source location, the high-tech for company a proposed improvements: need to avoid the resonance frequency of the tubing and the main excitation source frequency, but taking into account the pump speed and gear set can not be changed, thus recommends that near the pump inlet and outlet pipe to modify, change the material or shape and, through change tubing main resonance frequency, to avoid the excitation source 400Hz section frequency. |

| Previous:2016 do you really use screw refrigeration compres |

| Next:Mode locking failure of 2016 vertical injection mo |

| [ Back ] [ Print ] [ Shut down ] |

中文

中文 English

English